AGT-USA

Graphic Chillers

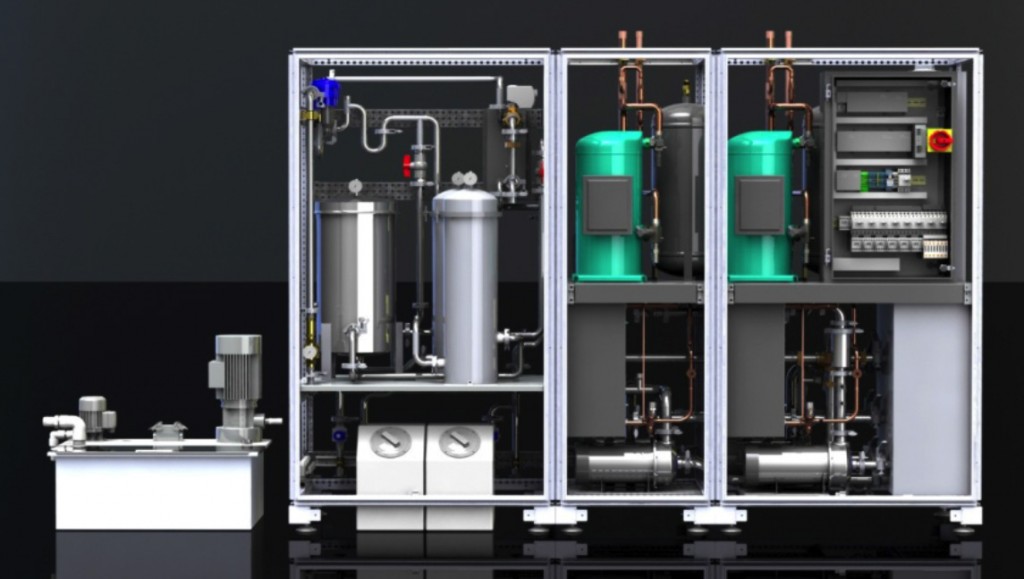

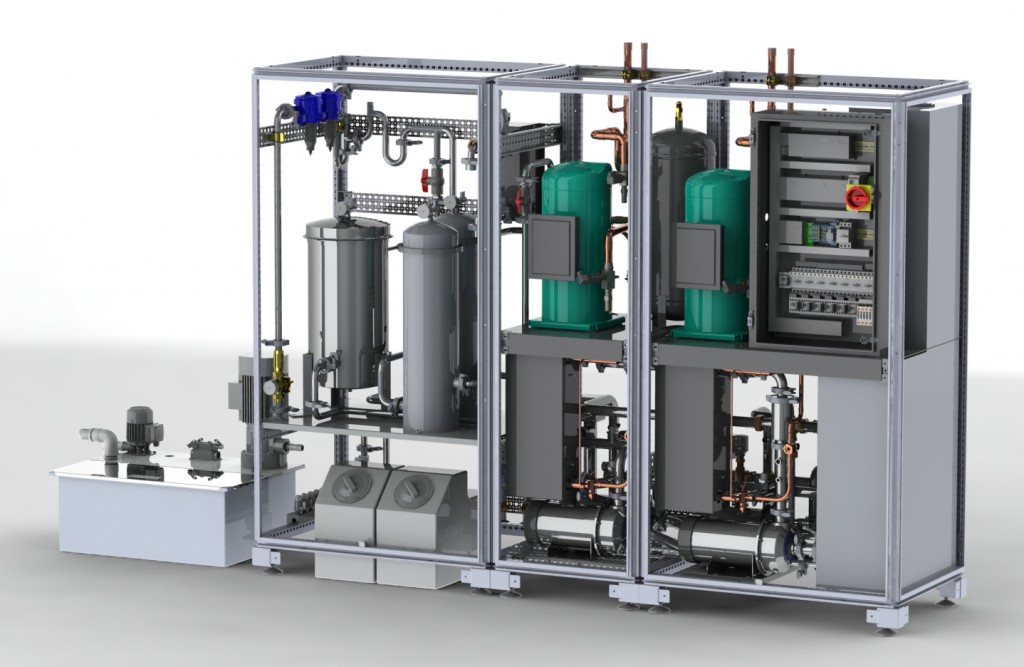

AGT offers a variety of refrigerant-based chiller systems engineered to remove heat and maintain precise temperature control in high heat generating processes. Each AGT system is designed to withstand the rigors of a 24/7 production schedule. AGT systems are a unique design of refrigeration, electronic control and diagnostics technology, assembled in a modular framework, delivering a highly functional and visually pleasing display.

AGT has established its product line encompassing many of the primary components ancillary to a sheet fed printing press. This unique ‘one-stop sourcing’ solution offers printers and press manufacturers significant benefits. For example, coordination of design and operation across the AGT product line helps ensure an integrated system’s efficient performance without concern for incompatibility among dissimilar vendors. Warranty work, periodic maintenance, and repairs are also facilitated in this regard. Single sourcing affords customers packaged pricing discounts and simplifies the financing process. Finally, and most importantly to a printer with press problems, AGT offers singular accountability with no finger pointing. These and other substantial benefits are well-recognized by customers and most importantly press manufacturers, enabling the AGT to gain increasing revenue per installed press.

AGT has secured the unique position as an approved component supplier to the vast majority of the major press manufacturers selling in the U.S. No competitor can make such a claim. Finally, continuous innovations helps AGT differentiate itself in a manner that is difficult to match. AGT focuses its sales efforts into two main segments within the North American print industry.

Combination Chillers

Dual Conductivity Detailed

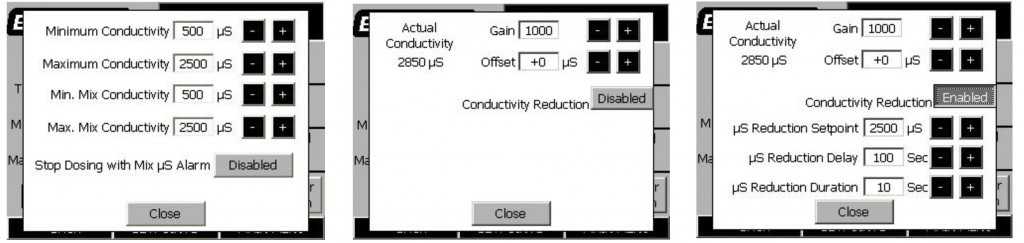

AGT’s Dampening Solution system utilizes an advanced Dual Conductivity Monitoring process.

Through our easy to navigate touch panel PLC interface we are able to not only measure and display the conductivity of the dampening solution being supplied to the press but we can also display and control the following:

- Alarms with settable limits for both High and Low conductivity.

- Monitoring of freshly mixed solution as it enters the Dampening Solution tank.

- Stop dosing if the fresh mix conductivity is outside of the range as defined by the operator.

- High Conductivity Reduction: When enabled, the Dampening Solution system will automatically dump a portion of the contaminated solution and replace it with fresh solution based on operator defined setpoints.

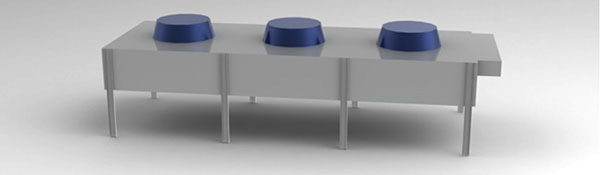

UV Lamp Chillers

AGT’s UV lamp chillers incorporate the same build quality and workmanship found in the combination chillers. From high-efficiency scroll compressors to stainless steel internal plumbing, the AGT UV lamp chiller is built to perform and built to last.

Offering a wide range of capacities, there is an AGT UV chiller to fit any need. We can also incorporate extra zones for special applications.

A roof mounted condenser is standard but side mounted self contained condensers, or water to water condensers are also available.

Combination / UV Lamp Chilling

The AGT UVC is an all-in-one package that includes UV lamp and Roller temperature control in addition to Dampening Solution control. The Siemens PLC touchscreen controls and monitors the entire package. This compact, space saving design will also save on power consumption as only one set of compressors needs to be employed. As always, function and aesthetics are combined perfectly in this beautiful and extremely functional piece of equipment.

Combination Chiller w/ Integrated FloClear filtration

AGT offers a solution that fully integrates our chillers with the FloClear fountain solution filtration technology. We have fully incorporated the control and monitoring of the FloClear into a single Siemens PLC. The FloClear filtration technology is available on both the combination chillers and the combination/ UV chillers. (as seen above)